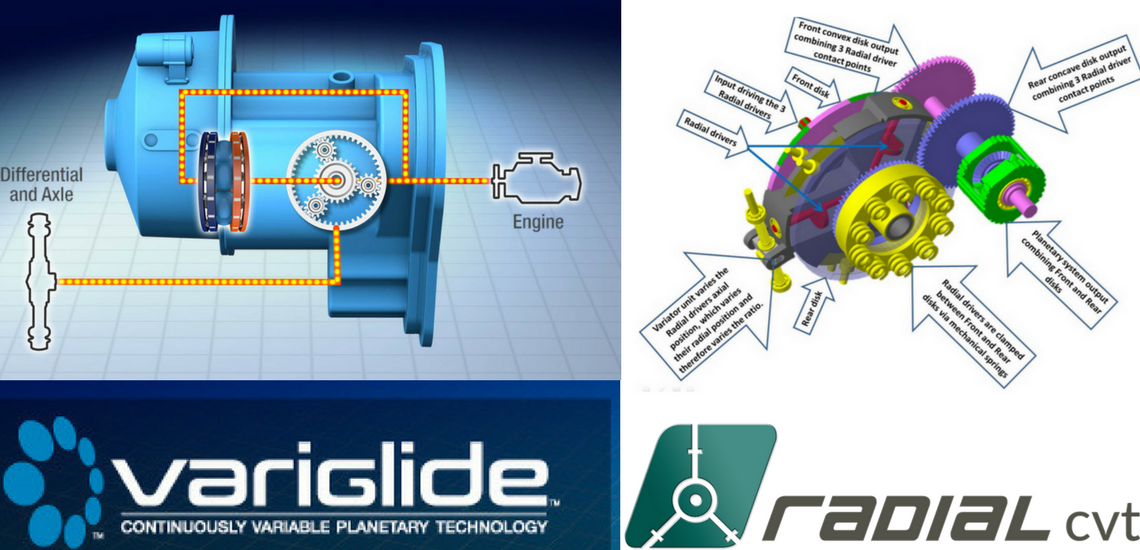

Comparison Between Varibox's RADIALcvt and the Variglide Planetary Variator From Dana

As demand for continuously variable transmissions (CVTs) within the small passenger vehicle market grows, competition to develop practical and cost effective alternative CVT solutions intensifies. Making particular headway is American engineering firm Dana, with its Variglide Planetary Variator CVT, scheduled for production in 2020.

This month, we compare the Varibox RADIALcvt against Dana’s Variglide, paying particular attention to each CVT’s mechanical efficiency and production cost. Below is a step by step breakdown of the Variglide Planetary Variator CVT and how it measures up against the RADIALcvt:

Traction Fluid

Variglide: The torque converter is coupled to a traction fluid variator that is integrated into what is essentially a 3 or 4 speed automatic transmission. The variator thus provides the ratios in between the 3 or 4 stepped gear ratios.

RADIALcvt: A typically electric actuated automated dry clutch is coupled to a variator which produces two outputs, combined in a planetary system.

Ratio Range

Variglide: When changing stepped ratios and thus also changing power paths, the variator has to shift through its whole ratio range which takes time. The result can be a power interruption but the disengaging clutch and engaging clutch can overlap to smooth the transition. According to a recent Variglide patent specification (WO2016160360A1) the variator ratio range is in the order of 1.88 to provide an overall ratio range of 1.88^4=12.5 if coupled to a 4 speed automatic.

RADIALcvt: The ratio range factor is 4.7 (not optimized in the first small passenger vehicle concept design) which is more than the typical 4.5 of a 5-speed manual transmission in a small passenger car.

If two ratios are included in the same way as the 3 to 4 ratios in the Variglide, the RADIALcvt ratio range will be 4.7^2 = 22, which is much higher than that of the Variglide CVT concept. The two ratios for the RADIALcvt can be implemented via electrically actuated automated manual transmission(AMT) technology.

Hydraulic Control and Clamping

The Variglide requires hydraulic clutch control whilst Varibox’s RADIALcvt does not. Furthermore, because of the variable input radius on the planet balls the Variglide requires a variable clamping force on the planet balls and thus some form of variable hydraulic clamping system is required.

On the other hand, the friction drive input radius in the RADIALcvt is constant, meaning that a constant clamping force is required and this is accomplished by mechanical springs. Thus, the RADIALcvt even with a two speed AMT integrated, does still not require a hydraulic system.

Mechanical Efficiency

All the power paths of Dana’s Variglide CVT have two friction drive interfaces in series as compared to the RADIALcvt having only one friction drive interface in series. The RADIALcvt’s mechanical efficiency should therefore be around 50% of that of the Variglide. Mechanical efficiency in the Variglide is further reduced by the power consumed by the hydraulic system.

Spinning Losses

The planet balls in the Variglide spin at about 3 times the engine speed. No components in the RADIALcvt spin faster than the engine, thus minimizing spinning losses. The surface rolling speed in the traction drive interface of the RADIALcvt is the same for all ratios for a given engine speed, and therefore the traction coefficient also remains constant which therefore also results in a constant clamping force.

Manufacturing Cost

Variglide: The relative small planet balls and its relatively small distance from the contacting ring center will result in very high maximum point contact stresses, typically around 4 GPa. There is thus a requirement for special steels or ceramics leading to increased manufacturing costs.

RADIALcvt: Because the RADIALcvt variator is concentric with the engine flywheel, the variator disks can be close to flywheel size which is relatively large. Therefore, a large output friction drive radius is created and this, together with its variator 6 parallel power paths, result in contact stresses of less than 2 GPa. As a result, there is no need for special steels, lowering manufacturing costs. The traction interface of the RADIALcvt also includes line contact which further reduces contact stress.

The Verdict

After an in-depth look at Varibox and Dana’s CVT technologies, the RADIALcvt emerges as a simple and cost effective transmission for small passenger vehicles with a ratio range up to 4.7. The RADIALcvt is also a flexible and scalable solution which can be adapted to provide a second ratio (for example using automated manual transmission technology without a hydraulic control system) to extend its ratio range to 22, for higher powered vehicles which is outside the range of any automotive application. Considering that the 9 speed ZF automatic transmission has a ratio range of 9.8, this proves a distinct competitive advantage.