International Search Authority Endorses SA CVT Innovation to Advance in Patent Process

SA based Intellectual Property firm optimistic following ISA’s acknowledgement of patent novelty

Varibox CVT Technologies (Pty) Ltd, this week confirmed the receipt of their International Search Report outcome, following an international PCT patent application. After an extensive world-wide search process, the RADIALcvt, a new multi-parallel power path friction drive Continuously Variable Transmission (CVT) concept, received a Category A result, indicating that there is no objection to its novelty, inventiveness and industrial application.

In the written opinion accompanying the ISA (International Search Authority) search report, the PCT examiner could not find any existing, prior art similar to the unique configuration used in the RADIALcvt. Varibox therefore did not need to modify any of the 12 claims in the initial PCT patent application ensuring comprehensive protection of the concept in whichever form it is implemented.

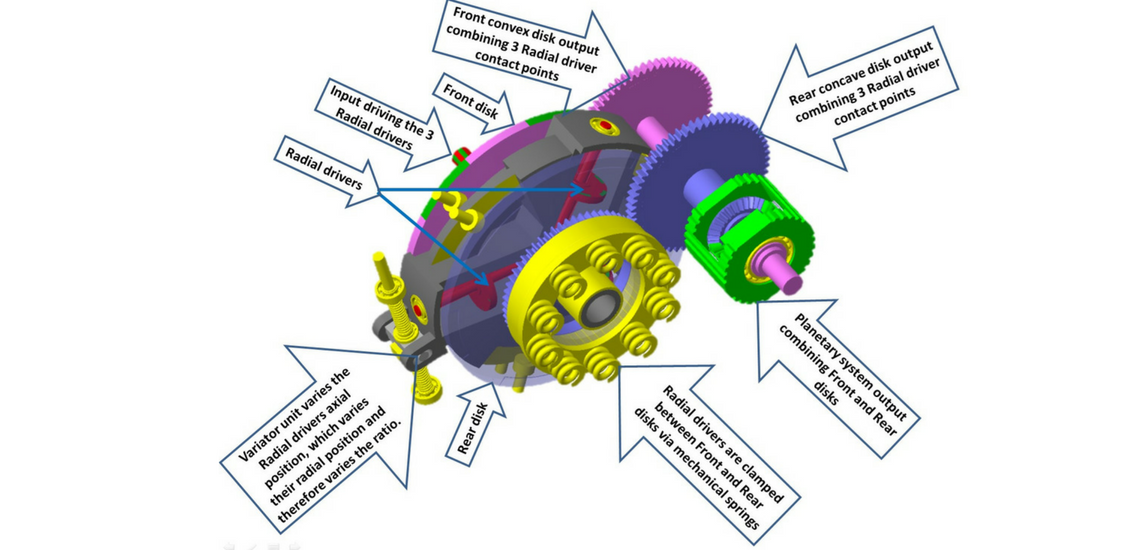

The RADIALcvt design is based on a functioning principle that has a single friction drive interface in series and features at least 6 power split friction drive parallel paths. A constant input radius on the friction drive input make it possible to use a constant clamping force which is provided by mechanical springs and as a result, the RADIALcvt has no hydraulic control system. In addition to this, the RADIALcvt has a very large radius variation on the friction drive output which provides the ratio variation and because the radial drivers are clamped between two opposite rotating disks, the force on the drivers are largely cancelled out. The first ratio of the RADIALcvt is hard geared to eliminate the “kerb test” issue common with push belt CVT’s.

Other unique aspects of the Varibox invention are that it only has one steel-on-steel, traction fluid lubricated, friction drive interface in each power path, has a compact design, produce high mechanical efficiency and does not feature any hydraulic control system. It can further serve in both a hybrid vehicle and as an energy recovery device.

While developing the RADIALcvt, Varibox focussed on providing a scalable, disruptive piece of technology that would radically transform the global transmissions industry. This was achieved by providing a cost effective and mechanically efficient CVT solution suitable for automotive, outdoor power equipment (OPE), commercial vehicle and industrial market application.

The RADIALcvt share some similarities with the commercial Lepelletier transmission in that it is essentially a unique configuration, using well known and existing technologies as building blocks. The Lepelletier automatic transmission uses a unique configuration of existing planetary systems and existing clutch technology in an automatic transmission which very significantly reduced the number of components, while the RADIALcvt uses existing traction fluid technology used by all current commercial and developmental CVT’s to minimise the number of components, reduce manufacturing costs and minimise carbon emissions. As the RADIALcvt makes use of existing technology in a unique configuration; mass production development and development risk is significantly reduced. Since filing the patent in 1998, 15 million Lepelletier transmissions have been produced by 2010 and with Varibox now aggressively developing and marketing the RADIALcvt, the potential is there to recreate the Lepelletier phenomenon 19 years on.

Varibox MD Jan Naude notes that, the RADIALcvt offers some key differential factors which give it distinct mechanical and cost advantages.

“The input power of the RADIALcvt is divided into six parallel power paths, with each path encountering one friction drive interface in series, all existing commercial CVTs have at least two interfaces in series which produce a compounded friction loss. The stress in the metal on metal contact in the traction fluid friction drive can be kept below 2GPa because of the parallel power paths and thus avoiding expensive materials,” explains Naude.

Varibox CVT Technologies specialise in the development of alternative high mechanical efficiency CVT concepts, two of which have previously been granted world-wide patents in over 13 international countries.

The company is currently in the process of commercialising its innovations and is actively seeking strategic partners in industry and commerce.

Contact Jan Naude, Managing Director, jnaude@varibox.com for more info.