The Current Status of Commercial CVTs in Global Production

In 2016 we witnessed unprecedented growth in the production of Continuously Variable Transmissions with data from Bosch indicating that in 2012 pushbelt production was at 4.5 million units annually, while year on year growth remains strong to the present as well as for future forecasts. One in five cars with an automatic transmission currently have a CVT and by 2020 it will be one in four.

This month we examine current trends in the global CVT industry through the evaluation of CVTs at various stages of production by established manufacturers Dana, Torotrak, Bosch, LUK and German-based engineering establishment GIF-E.

Variglide by Dana

Currently, Dana is showing steady progression with their Fallbrook CVT variator called the Variglide. Production of this CVT in passenger vehicles is expected to begin in 2020. The Variglide consists of a torque converter coupled to traction fluid variator, integrated in what is essentially a 4-speed automatic transmission. The variator thus provides the ratios in between the 4 stepped gear ratios.

When changing stepped ratios (power paths) the variator steps through its whole ratio range. This takes time and in order to provide uninterrupted power transfer, the disengaging clutch overlaps with the engaging clutch similar to that of an automatic transmission.

The variator has a relative small ratio range. For example, if the overall transmission ratio range is 10, a variator coupled to a 4-speed automatic transmission only needs a ratio range of 101/4=1.7.

Because of the variable input radius on the planet balls of the variator, a variable clamping force is required and thus some form of variable hydraulic clamping is also necessary. All power paths have two friction drive interfaces in series and as a result the planet balls spin faster than the engine. The relatively small planet balls and their relative distance from the contacting ring center results in high contact stresses, typically around 4 GPa, necessitating the use of special steels or ceramics.

The Variglide is thus not a cost effective and simple transmission and directly competes with seven to ten speed automatic transmissions (including dual clutch, automated manual and CVT's). Due to a smaller number of components, the Variglide is expected to be cheaper than an equivalent seven to ten speed automatic transmission while its efficiency gains vs automatics should come from a higher number of ratios and minimised drag in the fewer number of clutches, compared to automatics.

Bosch Belt and LUK Chain CVTs

Bosch Transmission Technology and LUK continue to dominate the CVT market with Bosch’s steel belt based CVTs holding the majority of global market share, while LUK which specialises in chain based CVTs hold the remaining market share.

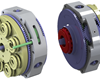

Cone-Ring Transmission (KRG) by GIF-E

The KRG, a continuously variable transmission innovation by German company GIF-E is specifically aimed at the Asian market. GIF-E’s Chinese partner, Zhejiang Defuli Automobile Transmission Company (Ltd) DFL is expected to launch the KRG into series production for the vehicle class of 150 N.m in the future. The KRG variator consists of two parallel spaced inverted cones with an axially adjustable ring clamped between the two cones. Friction drive between the cones and ring is also via traction fluid. There is thus two friction contact drive points transmitting all the power, resulting in high contact stresses, while the second cone, in high ratio rotates faster than the engine speed.

Although only the Bosch belt and the LUK chain CVTs are in production, 2017 looks to be another bumper year for the industry as production at Dana and GIF-E is eminent. There is however a gap in the market for innovations like the RADIALcvt and ROTORcvt by Varibox Technologies (PTY) Ltd that provide a simplistic, low cost alternative with increased mechanical efficiency resulting in low fuel consumption and decreased carbon emissions.