Exciting Times Ahead for Electric Driving

Massive shift towards EV performance however calls for more efficient component, transmission, battery technologies.

Electric vehicles (EV’s) are expected to play a leading role in revolutionising the global automotive industry within the next 10 years, according to latest research, but this will depend on a successful, sustained effort to improve efficiency and performance, while reducing costs associated with manufacturing and maintaining EV’s especially the battery cost and life.

It is indeed, the season for EV’s, and justifiably so. EV’s generally offer numerous advantages over internal combustion engines; clean energy, low operating costs and even lower maintenance costs, all positive factors which have seen even government officials encouraging a wholesale adoption of EV’s as propulsion alternatives.

France, for example, intends to end the sale of gas-and diesel-powered cars by 2040, Indian regulators want only electric cars sold in the country by 2030. Britain, in July 2017, announced plans to ban all new petrol and diesel cars by 2040, while in Germany, a new program will require CO2 emissions lowered 25-35% for cars and 30-40% for vans by 2030.

Major players in the global automobile industry have already begun planning for a dramatic decline in demand for the combustion engine. Big automobile manufacturers are reportedly shifting towards electrics at a faster pace than ever seen before.

As recently as June 2017, Volvo Car Group announced that it would have pulled the plug on its full gas/diesel cars by 2025. The giant Swedish car-maker will instead, focus on hybrid and full electric motors in its next new models. Tesla on the other hand plans to massively increase its EV manufacturing to 500,000 units per year from 2018.

Projected market figures on EV’s demonstrate encouraging trends too. A 2017 PwC industry report estimates that 55% of all new vehicles will be electric cars by 2030. Additionally, the total EV market will peak at nearly 1 trillion dollars within 10 years, according to IDTechEx forecasts.

Inefficient EV batteries have long been a source of scepticism over the years, but recent breakthroughs in Li-ion battery technology have led to a steady fall in vehicle prices, improved driving ranges and performance, factors which have further fuelled consumer interest.

Recently, a Brookhaven National Laboratory research unlocked a means to reducing battery charging times, a key disadvantage previously cited by consumers and auto industry experts.

This massive shift towards performance calls for high efficiency in other EV components as well, and this includes transmission technologies.

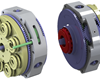

It is for this reason that Varibox CVT Technologies, a South African based IP company which specialises in developing mechanically efficient CVT concepts, designed the RADIALcvt, a CVT (continuously variable transmission) applicable across hybrid and pure electric vehicles.

The RADIALcvt as a traction drive with CVT capability, was designed for the specific purpose of addressing the low mechanical efficiency and complexity associated with current CVT technologies.

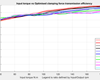

A number of simulations have proven advantages of CVT in pure electric vehicles, but low overall efficiencies accompanying current commercial CVT’s have in some cases totally eroded these benefits.

The RADIALcvt design comes with only one traction drive in series in its power path, whereas all other CVT’s have two. This way, the RADIALcvt concept starts off with the potential to have 50% of the traction drive losses in comparison to current CVT’s

Varibox’s RADIALcvt includes a constant clamping force via mechanical springs which allows the elimination of the hydraulic control and associated losses inherent in current CVT’s. All current CVT cannot function without a hydraulic control system.

In the RADIALcvt, the clamping force related bearing losses is only related to the output speed of the transmission. In all other CVT’s these losses are related to both the transmission and output speed. This gives the RADIALcvt an advantage in low ratios associated with partial load city driving where current CVT’s have their worst mechanical efficiency.

RADIALcvt technology, because of its simplicity, fundamental advantages and very high mechanical efficiency, is a superior innovation which performs better than any other CVT on the market.

Studies have shown that multi speed/cvt transmissions in EV can save up to 20% energy consumption and thus the direct effect of utilising 20% less batteries while still maintaining performance and range while reducing the weight and cost of the batteries.

The RADIALcvt innovation emerges as an excellent solution for pure electric vehicles in an age where consumers increasingly demand guarantees for higher performance and premium efficiency before making a purchase.

To learn more about the application of the RADIALcvt in pure electric vehicles, please download this white paper.

For any business-related questions, please send an email to jnaude@varibox.com